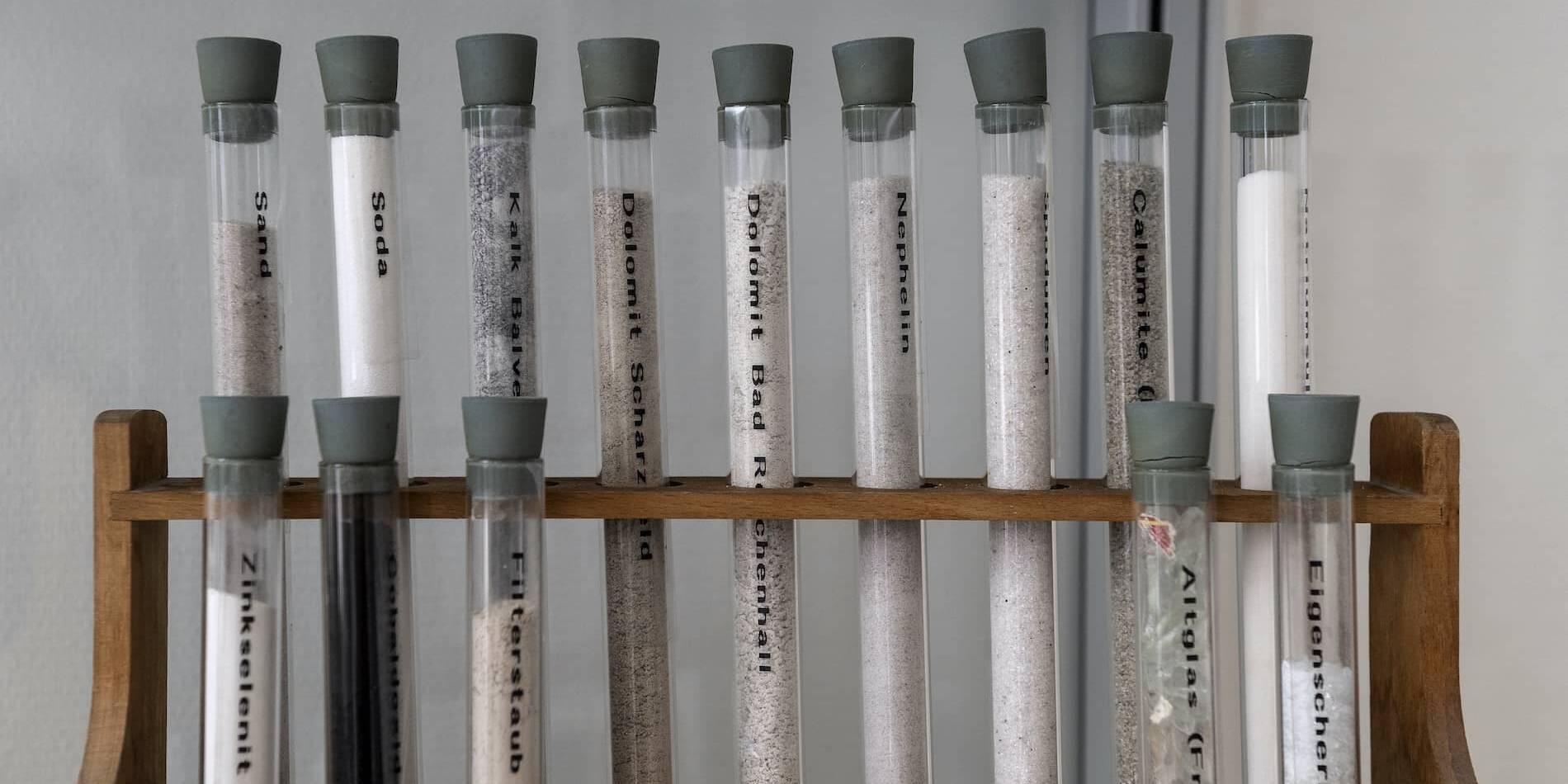

Raw materials

- ICP-OES analysis according to DIN 51086-2 of the elements or element oxides: Al, As, B, Ba, Ca, Cd, Co, Cr, Cu, Fe, Hg, K, Li, Mg, Mn, Na, Ni, P, Pb, S, Sb, Si, Sn, Sr, Ti, V, Zn, Zr

- X-ray fluorescence analysis (XRF) according to DIN 51001 and DIN 51418 ( >0.001 wt.% concentration), e.g. for analysing high-purity raw materials and other elements such as F, Cl, Br

- SEM-EDX examinations according to DIN ISO 22309, if necessary with image documentation, chemical scan analyses, mappings, line scans (depending on the order)

- X-ray diffractometry (XRD) based on DIN EN 13925 for analysing crystal structures

- Determination of loss on ignition according to DIN 51081 at different temperatures (e.g. 550 °C, 1050 °C, 1150 °C)

- Carbon determination using the Ströhlein incinerator at 1250 °C as total carbon (C), organic carbon (TOC) and inorganic carbon (TIC)

- Determination of the chemical oxygen demand (COD), e.g for sand, coke and basalt

- Determination of emission factors for the DEHSt and the UBA

- SO3 determination using the Ströhlein incinerator at 1250 °C

- Fe2+ detection with phenanthroline based on DIN ISO 14719

- Cr(VI) detection with diphenylcarbazide based on DIN 51086-3

- Determination of the redox potential and the redox number derived from this for batch calculations, e.g. for filter dust

- FT-IR spectroscopy according to ASTM E 1252 e.g. for plastic analyses

- Melting point determination, e.g. of plastics

- Analysis of inorganic filter aids and filter materials according to DIN EN 12902 for the treatment of water for human consumption

- Leaching tests

- Sieve analysis according to DIN 66165, depending on the order, e.g. 7 fractions (2 mm to 0.04 mm)

- Bulk density according to ISO 697, DIN EN ISO 60

- Moisture content of raw materials and mixtures based on DIN ISO 11465 and DIN 52331

- Microscopic examination according to ISO 8039 or using SEM-EDX according to DIN ISO 22309 of grain shape, surfaces and sizes

- Heavy mineral identification in the raw material using various heavy separation systems such as IGR-modified bumbling table, spiral separator and heavy liquid with a density >2.9 g/m³ for sample sizes ranging from grams to tonnes, followed by detection of the heavy minerals, e.g. using SEM-EDX

- Processing of raw materials, including by attrition and with a high-intensity rare earth roller magnetic separator to remove ferrous particles and further analyses, e.g. using ICP-OES

- Determination of HCl-insoluble components in raw materials, e.g. silicates in limestone

- Decrepitation test for raw materials, especially dolomite

- Determination of the oil number according to ISO 787-5

- BET analyses to determine the specific surface area

- Dose rate measurements (radiation dose per time unit, e.g. in µSv/h)

- DTA (differential thermal analysis) based on DIN 51004, DIN 51005, DIN 51006, DIN 51007

- TGA (thermo-gravimetric analysis)